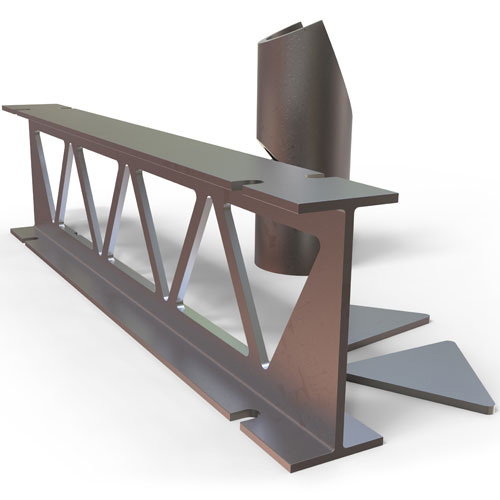

Our Nashville Division features a Peddinghaus PediBot-12oo robotic 6-axis plasma structural processing center.

This specialized machine can quickly cut bolt holes, slots, bevels, rat holes, multiparts, copes, flange thins, K cuts, web snipes, and more in all structural shapes including square and rectangular tube, beams, channel, and angle. The PeddiBot 1200 can also etch part numbers/assembly numbers or other designs on the surface of your parts.

Robotic 6-Axis Plasma Capabilities

- Beams – 4” thru 48”

- Square tubes – 3” to 16”

- Rect tubes – 3×4 thru 16×24

- Channels – 4” thru 18”

- Angles – 3” thru 10”

- Max profile – 48×16.5

- Max thickness – 2”

- Max profile weight & length – 350 lbs per ft

- Max length – 60’ infeed & outfeed

- Max bevel – 45 deg

- Etching capabilities

Benefits of 6-axis robotic plasma cutting

Our Peddinghaus PeddiBot-1200 is a 6-axis robotic cutting center that can quickly process holes, slots, bevels, rat holes, multiparts, copes, flange thins, K cuts, web snipes, and more in structural sections up to 48″ with ease. All of this can be done during a single process, eliminating and reducing your bottlenecks by having us deliver not only the stock structural steel to you, but already cut and marked “erector set kit” per your requirements. You can bring in this “kit” and go right to assembly or priming/painting. This allows small and large structural fabricators to take on more work that would have previously created a bottleneck or would have consumed too many man-hours to be able to take on the job. Partner with us and we can process your structural shapes so you can reduce your lead times to your end-users.