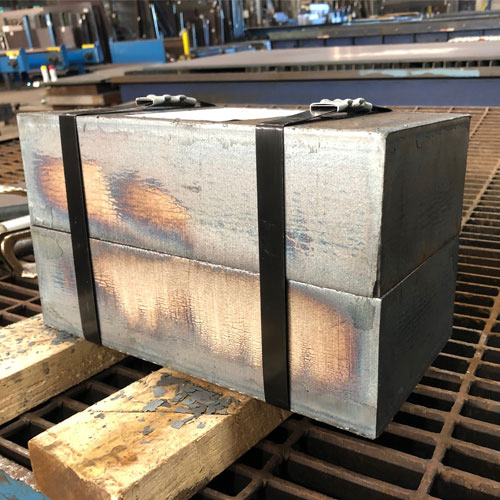

We have multi-head oxy-fuel flame cutting tables capable of processing up through 8″ thick plate with a table size capacity of 120″ x 488″ able to take on large plate sizes and volume.

The multi-head system makes for more efficient cutting to reduce your lead times and cost. Great for heavy equipment parts and more, we can pull heavy plate directly from our inventory and burn it per your drawing.

Oxy-Fuel Flame Cutting Capabilities

- Carbon Steel Plate: 3/8″ through 8″ (3/16″ through 1″ should generally be plasma or laser cut)

- Alloy Plate: 1/2″ and up

Advantages of cutting with Oxy-Fuel Flame Torches

Capable of reaching burning temperatures of over 6,000° F, Oxy-Fuel CNC flame cutters use a mixture of fuel gas and oxygen to create a concentrated jet hot enough to effortless cut through thick steel. Flame cutting allows us to cut your net or near-net shapes from plate as thick as 8″. Let us cut your thick plate to save you on expensive consumables and additional operations. While utilized widely in the production of heavy equipment, flame-cutting is used in many industries for a variety of applications. Flame cutting is used to cut steel that is generally too thick to cut via any other burning process such as laser or plasma.